RESULTS

Estimated results:

- Experimental set-ups for nanocomposite (NC) production and analysis

- Experimental set-up for deposition plasma analysis

- PLD deposition of NC dielectric thin film matrix; optimization

- Analysis of structural and morphological properties of thin films

- PLD deposition of metallic nanoparticle NC constituents

- Analysis of structural and morphological properties of nanoparticles

- PLD deposition of NCs; optimization

- Analysis of structural and morphological properties of NCs

- Analysis of optical/magnetic functional properties of NCs

- Correlation between optical or magnetic properties of NC and NC constituents

- Analysis of PLD deposition plasma; correlation with NC and constituent properties

- Optimized process for production of NCs with improved optical or magnetic properties for applications

Results obtained:

- Analysis of thin films and NP

- thickness and roughness: profilometer - National Institute for Laser, Plasma and Radiation Physics NILPRP

- composition, phases, structure: XRD - National Institute for Materials Physics NIMP

- morphology: SEM and TEM microscopy, EDAX - University Politehnica of Bucharest UPB

- Deposition and analysis of the thin film (matrix)

- deposition of dielectric thin films (Al2O3; TiN; YBCO)

- analysis of the effect of irradiation parameters (gas type and pressure, laser en/pulse) on thin films properties

- analysis of structural and morphological properties of the deposited films:

- amorphous (vacuum deposition) or polycrystalline (gas atmosphere) films

- gas pressure, not type, has effect => target species-gas interactions are of hydrodynamical nature

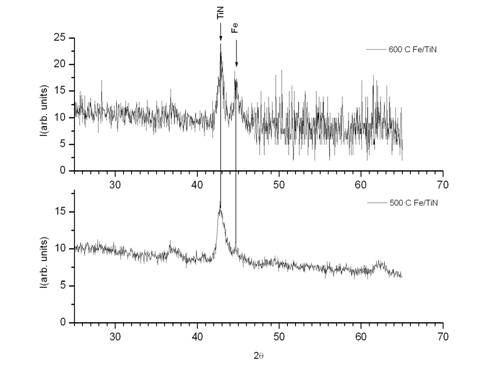

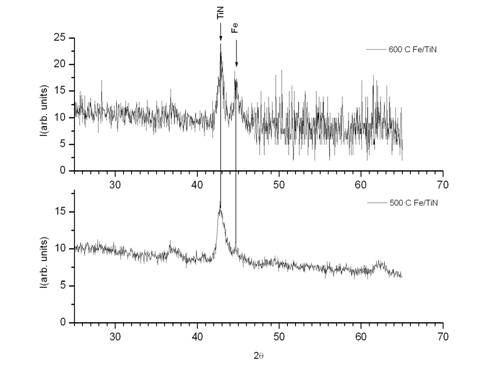

- TiN: XRD results => complete reaction of Ti with N2 to form cubic TiN phase

XRD spectra of a thin film obtained by ablation of a Ti target in an N2 atmosphere

- Deposition and analysis of NPs

- deposition of various metallic NPs on various thin films or directly on Si(100) substrate

- study of effect of laser parameters (en/pulse, pulse no) on the structural and morphological properties of the NPs

- study of the effect of other primary parameters (gas type and pressure, substrate temperature, target-substrate distance) on NP physical properties (size, shape, structure)

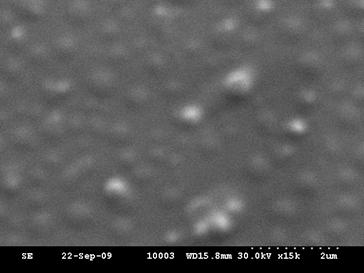

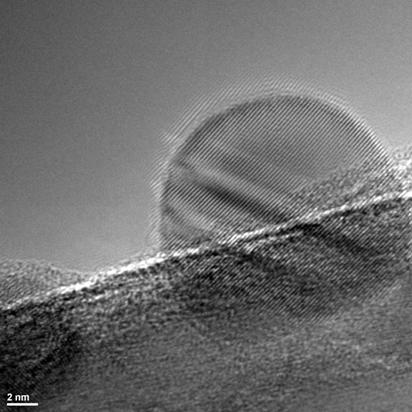

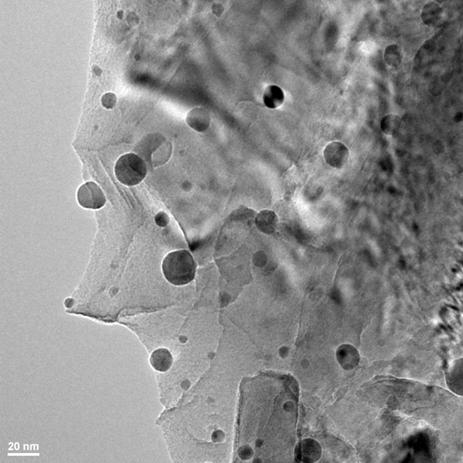

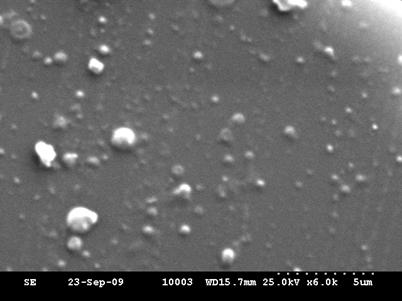

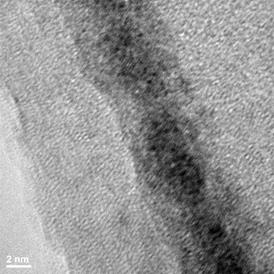

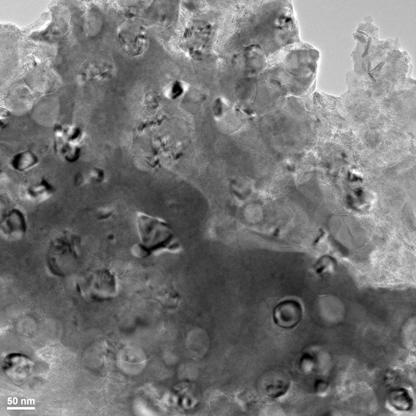

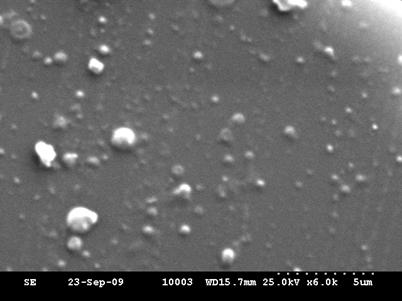

- SEM, TEM microscopy => spherical NPs having dimensions 2 nm – hundreds nm, distributed regularly over surface

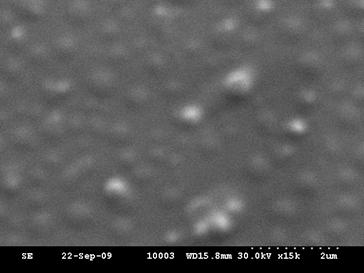

SEM of Fe NPs/Al2O3

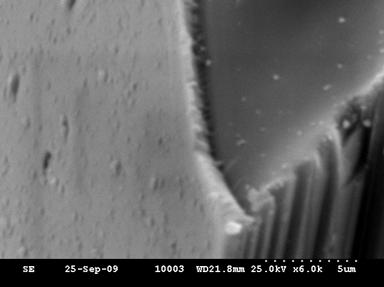

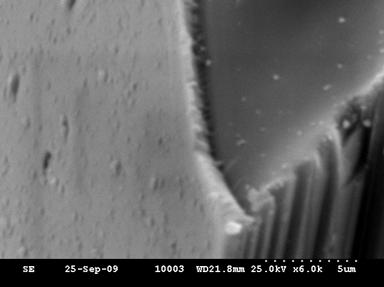

SEM of Fe NPs/TiN

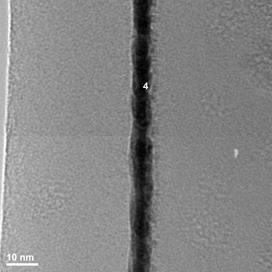

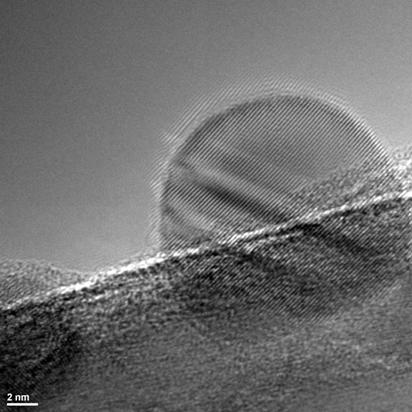

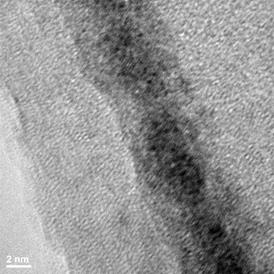

TEM of Fe NPs/ Al2O3

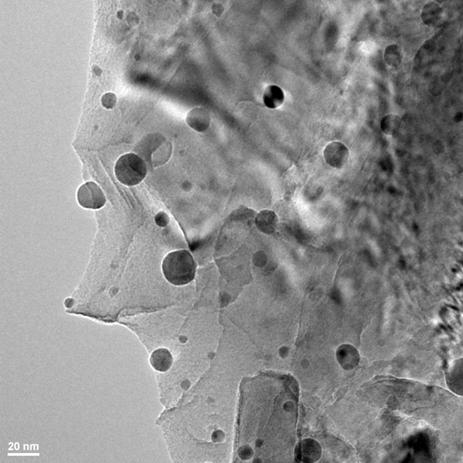

TEM of Fe NPs/ Al2O3

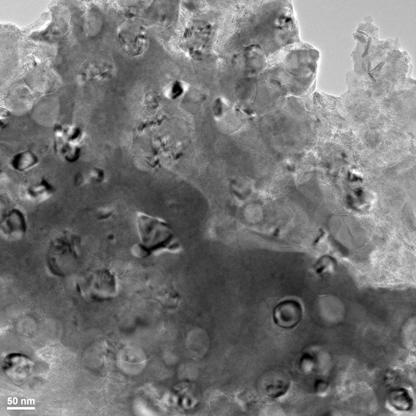

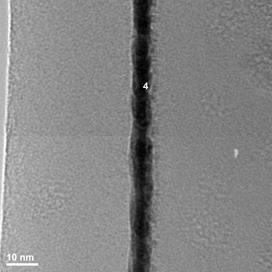

Irradiation in a nitrogen atmosphere leads to some non-spherical NP ← formation of iron nitrides (magnetic) ?

TEM of Fe NPs/TiN

- EDAX => NP composition

- NP structure: policrystalline or single crystalline, even if surrounding matrix is amorphous Þ important practical result

- the percolation limit was not reached in our experimental conditions Þ NCs properties will be given by separated NPs

- Au NP are close to percolation limit (observation of elongated; NP surface density is very large )

- in some conditions self-assembly of NPs over surface is visible

Presence of self-assembly into lines of Fe NPs over Al2O3 surface

Analysis of interactions between NC elements: thin film and NP

- Thin film structure has no effect on NP structure for small NP density

- Au NPs in Al2O3 : large NP density Þ NPs and thin film interact strongly

- Increase of deposition temperature increases amount of oriented material (especially NPs), as shown by XRD

- Target-substrate distance affects NCs only close to percolation limit: NP dimensions are larger closer to target.

Temperature dependence of NC element crystallinity. Top: 600 °C; Bottom: 500 °C.

- Preliminary measurements of magnetic properties of NCs (Fe/Al2O3)

- presence of hysteresis

- values of magnetic moment and coercivities compare favorably with results published by other authors

Magnetization curves m(H) for 10 K (left) and 200 K (right) (over/under blocking temperature) for Fe/Al2O3 nanocomposite deposited at room temperature. Original experimental data (includes diamagnetic signal of probe holder).

Deposition and characterization of FM core/AFM shell nanoparticles in various matrixes

- FM Fe and Co NPs were embedded in non-magnetic matrixes such as Al2O3

- The effect of deposition gas nature/pressure and post deposition oxygen pressure on NP dimensions, structure, composition and magnetic properties was studied

- For practical data storage applications, small (˞ 2 nm) NPs must be separated and partially oxidized. This was efficiently obtained by vacuum deposition and post deposition oxidation.

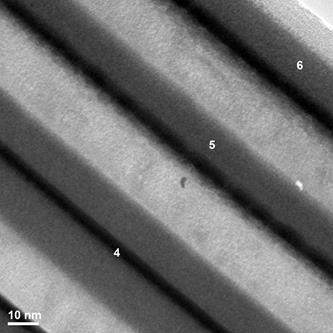

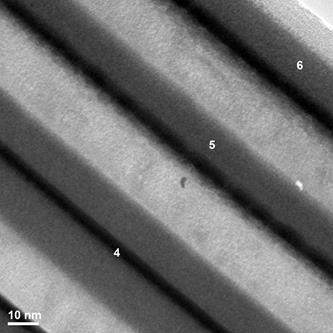

Cross-section TEM image revealing the presence of metal Co core/Co oxide shell NPs embedded in a non-magnetic Al2O3 matrix

- Both core-shell NPs and elongated FM NPs surrounded by an AFM or ferromagnetic area and embedded in a non-magnetic matrix have a higher blocking temperature due to exchange bias, as well as larger magnetization

TEM of elongated Co NPs surrounded by Co oxide and embedded in an Al2O3 matrix obtained by deposition in 10-5 mbar oxygen

- Matrixes must be chosen to ensure formation of separate NPs on surface; this is obtained for Al2O3 , which also prevents further oxidation of NP surface

Layers of Co (black) deposited on Cr2O3 (dark gray) and Al2O3 (light gray). The former matrix leads to continuous films; the latter leads to separate NPs. Co obtained with the same number of pulses in all cases

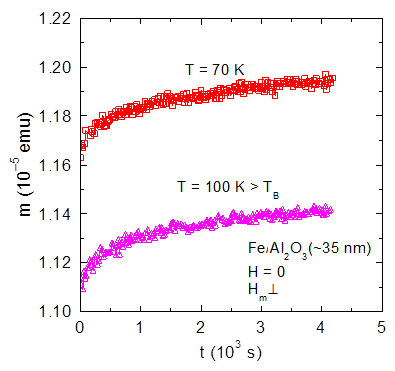

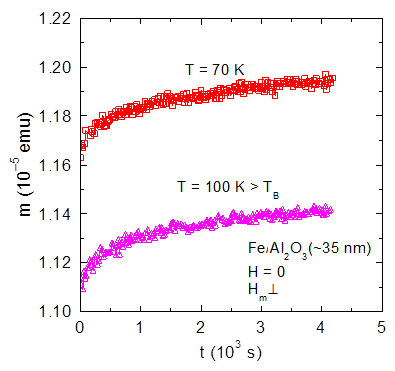

- Superferromagnetic (SFM) behavior was revealed using time relaxation of the magnetization in nanocomposites with large separation (35 nm) between rows of Fe NPs and in perpendicular applied field H

Remnant magnetization m(T) for T > TB in Fe/Al2O3 nanocomposites with a large separation between Fe NP layers, showing an increase with t; this indicates the presence of a memory effect characteristic for SFM

|